60-80TPD Cikakkun Injin sarrafa Shinkafa Tushen

Bayanin Samfura

Paddy parboiling kamar yadda sunan jihohi shine tsarin hydrothermal wanda sitaci granules tare da a cikin hatsin shinkafa suna gelatinized ta aikace-aikacen tururi da ruwan zafi. Niƙan shinkafa da aka fasheinjin yin shinkafayana amfani da busassun shinkafa a matsayin ɗanyen abu, bayan tsaftacewa, jiƙa, dafa abinci, bushewa da sanyaya bayan maganin zafi, sannan danna hanyar sarrafa shinkafa ta al'ada don samar da samfurin shinkafa. Shinkafar da aka gama da ita ta cinye abincin shinkafa sosai kuma tana da ɗanɗano mai daɗi, haka nan a lokacin da ake tafasawa ta kashe kwaro tare da sanya shinkafa cikin sauƙi a ajiye.

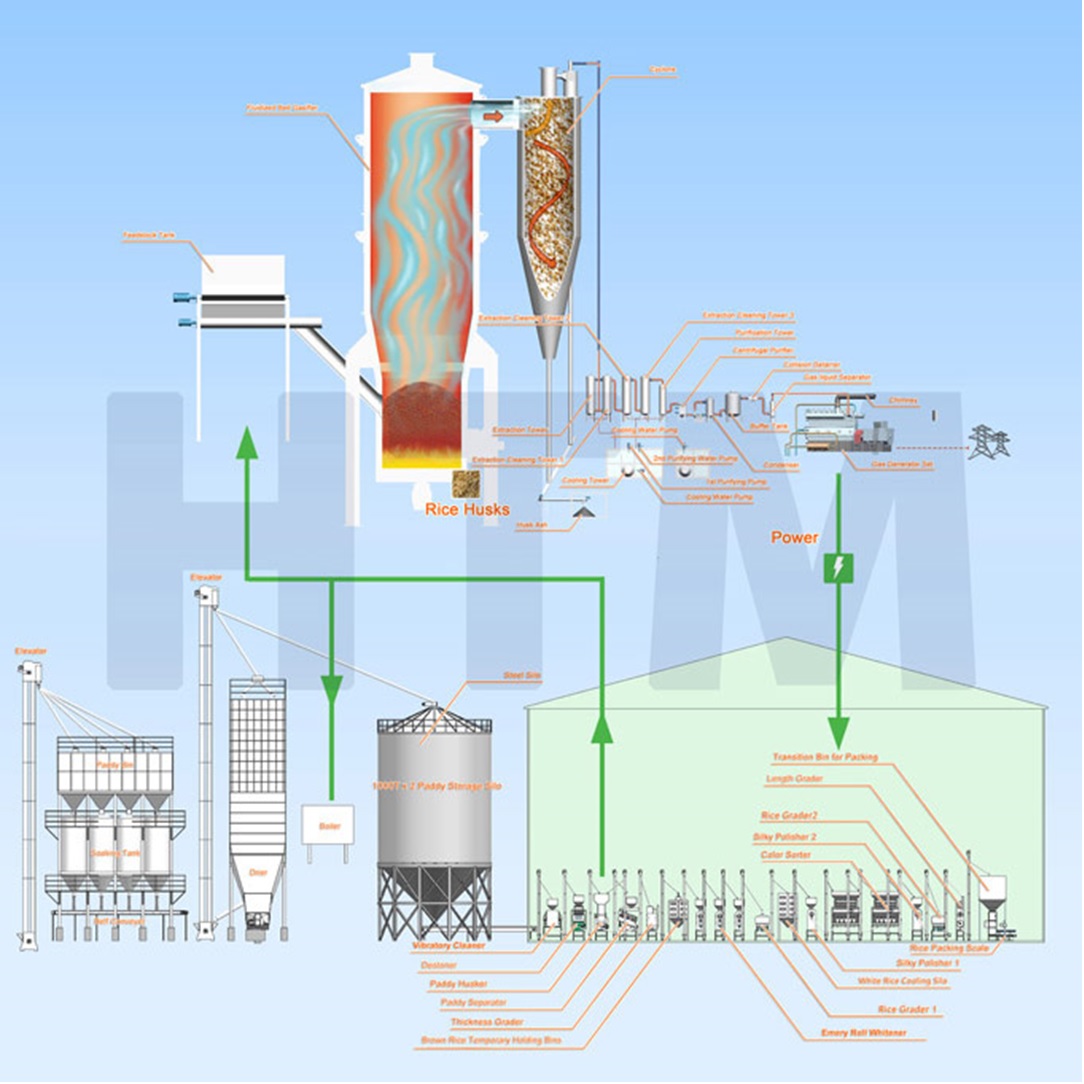

Muna iya samar da cikakke na zamani na atomatikparboiled shinkafa milling shukatare da jerin iya samarwa don buƙatar ku. Cikakken injin niƙan shinkafa yawanci ana yin shi ne da manyan sassa biyu: sashin dafaffen shinkafa da sashin niƙa shinkafa.

Cikakkun bayanai na Tsari don Niƙan Shinkafa Baƙaƙe kamar haka

1) Paddy Cleaning:A cikin wannan mataki muna cire datti daga paddy.

A fara tsaftace shinkafar domin a cire bambaro, duwatsu, igiyar hemp, sauran manyan tarkace da datti kamar kura da aka gauraya cikin shinkafar. Idan paddy yana da ƙura a lokacin da yake jiƙa zai gurɓata ruwa kuma ya yi tasiri ga abincin shinkafa. Har ila yau, bayan aikin tsaftacewa, za a iya kauce wa gazawar kayan aiki na ƙasa ko lalacewa ga abubuwan da aka gyara, wanda shine mahimmin tsari na cikakkiyar kayan aikin dafaffen shinkafa.

2) Paddy Soaking:Manufar jiƙa ita ce sanya paddy ya sha isasshen ruwa, haifar da yanayi don man sitaci. A lokacin tafiyar sitaci liƙa paddy dole ne ya sha sama da kashi 30% na ruwa, ko kuma ba zai iya cika tururi da paddy a mataki na gaba ba don haka ya yi tasiri ga ingancin shinkafa.

a. Ta hanyar vacuuming, yawan zafin jiki, da matsi, shinkafar ta kan cika ruwa cikin kankanin lokaci, ta yadda ruwan shinkafar ya kai fiye da kashi 30%, wanda hakan ya zama wajibi ga sitacin shinkafar ya zama cikakken gelatin. a lokacin aikin dafa abinci. A cikin layin samar da shinkafa, wannan sashin sarrafa shi shine sashe na asali kuma mai mahimmanci.

b. Dangane da iri-iri da ingancin shinkafa, yawan zafin jiki yakan kasance digiri 55-70, kuma lokacin jiƙa shine sa'o'i 3.5-4.5.

3) Tufafi da tafasa:Bayan jika cikin endosperm ya sami isasshen ruwa, yanzu lokaci yayi da za a tururi paddy don gane sitaci. Yin tururi na iya canza tsarin jiki na shinkafa da kiyaye abinci mai gina jiki, don ƙara yawan samarwa da kuma sa shinkafa cikin sauƙin adanawa.

A cikin wannan tsari, ana amfani da tururi mai zafi da zafi mai zafi. Dole ne a sarrafa zafin jiki, lokaci, da daidaituwar yanayin tururi ta yadda sitaci a cikin shinkafa zai iya zama cikakken gelatinized ba tare da wuce kima ba.

Lokacin da sitaci gelatinization ya isa, launi na sarrafa ƙãre parboiled shinkafa ne m zuma-launi.

Ta hanyar daidaita sigogin dafa abinci, ana iya sarrafa shinkafar da aka yi da ita tare da launi mai haske, launin duhu, da launi mai duhu bisa ga bukatun abokin ciniki.

4) bushewar Paddy Parboiled:Manufar bushewa ita ce rage danshi daga kusan kashi 35% zuwa kusan kashi 14%, don rage danshi zai iya sa shinkafa cikin sauki wajen adanawa da jigilar kayayyaki, da kuma kara yawan adadin noman shinkafa, saboda ana iya samun matsakaicin adadin shinkafa gaba daya idan shinkafa ta kasance. niƙa.

Muna amfani da zafin tukunyar tukunyar a yayin wannan aikin, ana juyar da ita cikin iska ta hanyar musayar zafi, kuma shinkafar ta bushe a fakaice, busasshiyar shinkafar ba ta da gurɓatacciya kuma ba ta da ƙamshi na musamman.

Tsarin bushewa ya kasu kashi biyu. Mataki na farko shine bushewa da sauri, wanda ke rage danshi na paddy daga sama da 30% zuwa kusan 20%, sannan a hankali bushewa don sanya paddy ya ragu sosai kuma ya rage yawan fashe kugu. Haɓaka duk ƙimar mita.

5) Paddy Cooling Parboiled:Ana aika busasshen paddy zuwa wurin ajiya a tsaye don ajiya na ɗan lokaci don a rage shi sosai kuma a sanyaya kafin a sarrafa shi. Gidan ajiyar silinda na tsaye yana sanye da fanka mai ɗaukar iska, wanda zai iya fitar da sauran zafi. Kuma a sanya shinkafar ta danshi daidai gwargwado.

6) Husking Shinkafa da Rabuwa:Yin amfani da injin hulling shinkafa don cire busasshen busasshen busasshen. Bayan jiƙa da tururi zai zama da sauƙi a husk paddy da adana kuzari.

Ana amfani da mai raba paddy don raba shinkafar launin ruwan kasa daga paddy ta hanyar bambance-bambancen da suke da shi a takamaiman nauyi da juzu'i a sassa uku: paddy, shinkafa launin ruwan kasa, da gauraya duka biyun.

7) Rice Milling:Lu'u-lu'u na shinkafar da aka kayyade ya fi lokaci fiye da paddy na al'ada. Dalili kuwa shi ne, bayan jika shinkafar yana da sauƙin zama smectic. Don guje wa wannan matsala, muna amfani da injin niƙa mai busa da kuma ƙara saurin jujjuyawar injin shinkafa, ƙwayar shinkafar shinkafa ta ɗauki nau'in ciwon huhu don rage juzu'i.

An kera injin niƙan shinkafa ne don niƙan shinkafa, wanda fasaha ce ta ci gaba na injin niƙan shinkafa na duniya a halin yanzu don rage zafin shinkafar, abun ciki na bran ya ragu, kuma ya ragu.

8) Shinkafa goge:Tsarin gyaran shinkafar shine a goge saman shinkafar ta hanyar fesa ruwa, wanda ke samar da ɗigon gelatin mai santsi wanda ke tsawaita lokacin adanawa. Extended ɗakin goge goge don samar da shinkafa mai inganci. Shinkafa mai kyau yana zuwa ta injin goge, zai sa shinkafar niƙa ta zama launi mai kyau da sheki, don haka ƙara ingancin shinkafar.

9) Rice Grading:Ana amfani da na'ura mai sarrafa shinkafa don tace shinkafar da aka niƙa da kyau kuma daidai cikin nau'o'i da yawa: shinkafa babba, karaya babba, karyayyen matsakaici, ƙarami karye, da sauransu.

10) Kalar Shinkafa:Shinkafar da muke samu daga sama har yanzu tana da ‘yar shinkafa mara kyau, karyayyen shinkafa ko wasu hatsi ko dutse. Don haka a nan muna amfani da injin rarrabuwar launi don zaɓar shinkafa mara kyau da sauran hatsi.

Na'ura mai rarrabuwar launi shine na'ura mai mahimmanci don tabbatar da cewa za mu iya samun shinkafa mai inganci. Yin amfani da injin ɗin rarrabuwar launin shinkafa don warware mummuna, madara, alli, paddy, da kayan waje. An gwada siginar CCD yayin da babu komai. Idan aka gano cewa akwai shinkafa ko kazanta a cikin kayan, mai fitar da kaya zai busa kayan da ba su da kyau a cikin hopper.

11) Tushen shinkafar da aka gama:Ƙarshen shinkafa yanzu ya shirya dear all! Mu yi amfani da injin mu na awo da tattara kaya don sanya su zama jaka 5kg 10kg ko 50kg.

Wannan na'ura mai ɗaukar nauyi ta atomatik da aka raba ta ƙunshi akwatin kayan aiki, ma'aunin tattara kaya, injin ɗinki, da bel mai ɗaukar kaya. Yana iya haɗa kai da aiki tare da duk layin samar da shinkafa niƙa samfurin. Nau'in lantarki ne, zaka iya saita ta kamar karamar kwamfuta, sannan zata fara aiki. Don iyawar jakar tattarawa na iya zaɓar 1-50kg kowace jaka bisa ga buƙatarku. Daga wannan injin za ku sami shinkafa nau'in buhu kuma zaku iya ba da shinkafar ku ga duk abokin cinikin ku!

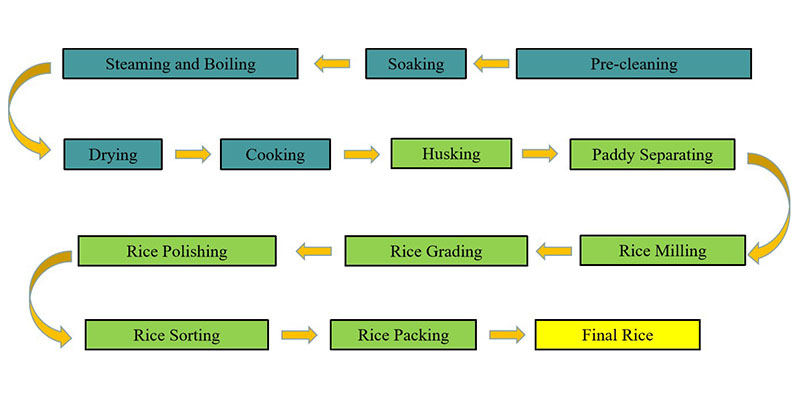

Za a iya ganin yadda ake sarrafa buhunan shinkafar cewa, aikin samar da cikakkiyar kafa na masana’antar paddy parboiling ya dogara ne da fasahar sarrafa farar shinkafa, ta yadda za a yi amfani da hanyoyin sarrafa makamashin ruwa kamar su jika, tari da tafasa, bushewa da sanyaya. da sannu a hankali. Gabaɗayan aikin noman shinkafar da aka daɗe ya haɗa da sassa biyu: ɓangaren dafaffen shinkafa da ɓangaren niƙan shinkafa, mai kamar haka:

A.Rice Parboiling Sashin:

Raw Paddy → Tsabtace Tsabta → Jiƙa → Tafiya da Tafasa → Bushewa → Sanyaya → Zuwa Niƙan Shinkafa

Sashin Milling B.Rice:

Paddy Parboiled → Husking da Rarraba → Niƙa Shinkafa → Gyaran Shinkafa da Grading → Kalar Shinkafa → Shirya shinkafa

Ƙa'idar zaɓi na fitar da tsire-tsire na paddy parboiling ya dogara ne akan fitarwa da ƙarfin injin miƙen shinkafa na gaba. Dole ne a sami isassun adadin shinkafar da aka daɗe kafin aikin farar shinkafar ya gudana. Fitowar kayan aikin da aka riga aka yi amfani da su dole ne ya zama mafi girma fiye da abin da ake samu na injin shinkafa na gaba. Idan hakan bai isa ba, ana iya haɗa raka'a biyu a layi daya. Lokacin da fitarwa ya yi daidai, yi amfani da pre-parboiler shinkafa tare da ƙarancin ƙarfi.

Majagaba a cikin masana'antar, muna tsunduma cikin kera kewayon Paddy Parboiling Plant mara kyau. Za mu iya samar da cikakkiyar shuka da bayar da sabis na shigarwa da sabis na horo. Idan kuna sha'awar wannan aikin, da fatan za ku iya tuntuɓar mu don ƙarin bayani.

Siffofin

1.Our Parboiling & Drying Shuke-shuke an yi su ne daga firamare da kayan gwaji na inganci na farko. Ƙarfin da aka yi kawai yana tabbatar da aiki kyauta da ingantacciyar inganci.

2.Uniform tururi na paddy yana yiwuwa ta hanyar tsarin rarraba tururi a cikin tankuna, Total uniform ingancin paddy cikin sharuddan dafa abinci da bushewa.

3.An ba da tankunan ruwa biyu a sama kamar yadda ruwan sanyi yana da sauƙin ɗauka.

4.Ba zubewa kamar yadda ƙãra tsawo na shuka tabbatar da mafi kyau kwarara taper zuwa rigar paddy.

5.Bushewa Uniform don shinkafa, kauri mai kauri don bushewa a hankali da tsayawa ba tare da samuwar hatsi ba.

6.Factory Fitted da tara shuka a cikin cikakken bolting da nadawa gine-gine, 90% na kayan da ake kerarre a cikin masana'anta, rage lokaci dauka a lokacin shigarwa.

7.Low makamashi amfani saboda ingantaccen zane na masu busawa da masu hawan kaya.

Ƙananan ma'aikata da ake buƙata don tafiyar da sashin kamar yawancin operatmachine don sanya su cikin jaka 5kg 10kg ko 50kg. Wannan injin nau'in lantarki ne, zaku iya saita ta kamar karamar kwamfuta, sannan zata fara aiki bisa ga bukatarku. Daga wannan injin za ku sami shinkafa nau'in buhu kuma zaku iya ba da shinkafar ku ga duk abokin cinikin ku!

Babban ginshiƙi mai gudana shine: Tsaftacewa - jiƙa - tururi - bushewa - husking - milling - gogewa da grading - rarraba launi - tattarawa.

Za mu iya samar da cikakkiyar shuka da bayar da sabis na shigarwa da sabis na horo. Idan kuna sha'awar wannan aikin, da fatan za ku iya tuntuɓar mu don ƙarin bayani.