Tsarin Gyaran Man Fetur: Gurɓatar Ruwa

Bayanin Samfura

Tsarin Degumming a masana'antar tace mai shine kawar da gurɓataccen ɗanɗano a cikin ɗanyen mai ta hanyar zahiri ko sinadarai, kuma shine matakin farko na aikin tace mai / tsarkakewa. Bayan dunƙule latsawa da kuma cire sauran ƙarfi daga iri mai, ɗanyen man yafi ƙunshi triglycerides da ƴan marasa triglyceride. Abubuwan da ba su da triglyceride ciki har da phospholipids, sunadarai, phlegmatic da sukari za su amsa tare da triglycerides don samar da colloid, wanda aka sani da ƙazantattun gumaka.

Rashin ƙazantaccen ɗanko ba wai kawai yana shafar kwanciyar hankali na man fetur ba amma har ma yana shafar tsarin aikin gyaran man fetur da kuma aiki mai zurfi. Misali, man da ba a dade ba yana da sauki wajen samar da man emulsified a cikin tsarin tace alkaline, don haka yana kara wahalar aiki, asarar tace mai, da amfani da kayan taimako; a cikin tsarin decolorization, man da ba a cire shi ba zai kara yawan amfani da adsorbent kuma ya rage tasirin discoloring. Don haka, cire danko ya zama dole a matsayin mataki na farko na aikin matatar mai kafin rage yawan man mai, canza launin mai, da deodorization na mai.

Hanyoyin ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun sun hada da hydrated degumming (ruwa degumming), acid refining degumming, alkali refining method, adsorption method, electropolymerization and thermal polymerization method. A cikin tsarin gyaran man da ake ci, hanyar da aka fi amfani da ita ita ce hydrated degumming, wanda zai iya fitar da phospholipids na hydratable da wasu phospholipids marasa ruwa, yayin da sauran phospholipids ba tare da hydrate suna buƙatar cire su ta hanyar lalata acid.

1. Ƙa'idar aiki na hydrated degumming (water degumming)

Danyen mai daga tsarin hakar sauran ƙarfi ya ƙunshi abubuwan da ke narkewa da ruwa, da farko sun ƙunshi phospholipids, waɗanda ke buƙatar cirewa daga mai don ba da damar hazo mafi ƙanƙanta da daidaitawa yayin jigilar mai da adana dogon lokaci. Rashin ƙazanta irin su phospholipids suna da halayyar hydrophilic. Da farko, za a iya motsawa da kuma ƙara wani adadin ruwan zafi ko electrolyte aqueous bayani kamar gishiri & phosphoric acid zuwa zafi danyen mai. Bayan wani ɗan lokaci, ƙazantar gumakan za a datse, a rage kuma a cire daga mai. A cikin tsarin gurɓataccen ruwa, ƙazantattun abubuwa sune phospholipid, da kuma wasu furotin, glyceryl diglyceride, da mucilage. Menene ƙari, ana iya sarrafa gumakan da aka fitar zuwa cikin lecithin don abinci, abincin dabbobi ko don amfanin fasaha.

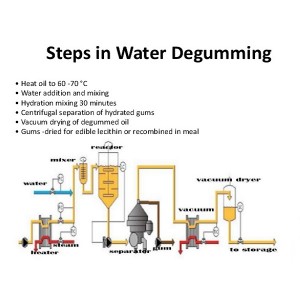

2. Tsarin hydrated degumming (water degumming)

Tsarin rushewar ruwa ya haɗa da ƙara ruwa zuwa ɗanyen mai, hydrating abubuwan da ke narkewa da ruwa, sannan cire yawancin su ta hanyar rabuwa ta tsakiya. Halin haske bayan rabuwa na centrifugal shine danyen mai, kuma lokaci mai nauyi bayan rabuwa na tsakiya shine haɗuwa da ruwa, abubuwan da ke narkewa da ruwa da man fetur, wanda ake kira "gums". Ana busar da danyen man da aka yi da shi a sanyaya kafin a tura shi wurin ajiya. Ana mayar da gumakan akan abincin.

A cikin masana'antar tace mai, ana iya sarrafa na'ura mai hydrated degumming tare da injin deacidification na mai, na'urar cire launi, da na'ura mai lalata, kuma waɗannan injinan sune abubuwan da ke tattare da layin samar da mai tsarkakewa. An rarraba layin tsarkakewa zuwa nau'in tsaka-tsaki, nau'in ci gaba mai ci gaba, da nau'in ci gaba mai cikakken ci gaba. Abokin ciniki zai iya zaɓar nau'in gwargwadon ƙarfin samarwa da ake buƙata: masana'anta tare da ƙarfin samarwa na 1-10t kowace rana ya dace da yin amfani da kayan aiki na wucin gadi, 20-50t kowace rana ma'aikata ta dace da yin amfani da kayan aikin ci gaba na ci gaba, samarwa. fiye da 50t a kowace rana ya dace don amfani da cikakken ci gaba nau'in kayan aiki. Nau'in da aka fi amfani da shi shine layin samar da ruwa mai tsaftataccen ruwa na tsaka-tsaki.

Sigar Fasaha

Babban abubuwan da ke haifar da hydrated degumming (water degenumming)

3.1 Girman ƙara ruwa

(1) Tasirin ƙara ruwa akan flocculation: Adadin da ya dace na ruwa zai iya samar da tsayayyen tsarin liposome mai yawan Layer. Rashin isasshen ruwa zai haifar da rashin cika ruwa da kuma mummunan flocculation colloidal; Ruwan da ya wuce kima yakan haifar da emulsification na ruwa-mai, wanda ke da wuya a raba kazanta da mai.

(2) Dangantaka tsakanin ƙara abun ciki na ruwa (W) da abun ciki na glum (G) a cikin yanayin zafin aiki daban-daban:

| low zafin jiki hydration (20 ~ 30 ℃) | W= (0.5~1) G |

| matsakaicin zafin jiki hydration (60 ~ 65 ℃) | W= (2~3) G |

| high zafin jiki hydration (85 ~ 95 ℃) | W= (3 ~ 3.5) G |

(3) Gwajin samfurin: Ana iya ƙayyade adadin da ya dace na ƙara ruwa ta hanyar gwajin samfurin.

3.2 Yanayin aiki

Yawan zafin jiki na aiki gabaɗaya yayi daidai da matsanancin zafin jiki (domin ingantacciyar ɗigon ruwa, zafin aiki na iya ɗanɗana sama da matsanancin zafin jiki). Kuma yawan zafin jiki na aiki zai shafi adadin ruwan da aka ƙara lokacin da zafin jiki ya yi girma, yawan ruwa yana da girma, in ba haka ba, yana da ƙananan.

3.3 Ƙarfin haɗuwar hydration da lokacin amsawa

(1) Rashin ruwa mara nauyi: Gum flocculation wani nau'i ne mai ban sha'awa a wurin mu'amala. Domin samar da wani barga mai-ruwa emulsion jihar, inji hadawa da cakuda iya sa droplets gaba daya tarwatsa, inji hadawa bukatar da za a tsananta musamman a lokacin da adadin kara ruwa ne babba da kuma zafin jiki ne low.

(2) Ƙarfin haɗuwar hydration: Lokacin haxa mai da ruwa, saurin motsawa shine 60 r / min. A lokacin samar da flocculation, saurin motsawa shine 30 r / min. Lokacin amsawar hadawar ruwa yana kusa da mintuna 30.

3.4 Electrolytes

(1) Daban-daban na electrolytes: Gishiri, alum, sodium silicate, phosphoric acid, citric acid da dilute sodium hydroxide bayani.

(2) Babban aikin electrolyte:

a. Electrolytes na iya kawar da wasu cajin wutar lantarki na ƙwayoyin colloidal kuma suna haɓaka ɓangarorin colloidal zuwa sedimentate.

b. Don canza phospholipids marasa ruwa zuwa hydrated phospholipids.

c. Alum: flocculant taimako. Alum na iya sha pigments a cikin mai.

d. Don chelate da karfe ions kuma cire su.

e. Don haɓaka koloidal flocculation kusa da rage yawan mai na flocs.

3.5 Wasu dalilai

(1) Daidaitawar mai: Kafin a samu ruwa, sai a tada danyen mai gaba daya ta yadda za a iya rarraba koloid daidai gwargwado.

(2) zazzabi na ƙara ruwa: Lokacin da ruwa, zafin jiki na ƙara ruwa ya kamata ya zama daidai ko dan kadan sama da zafin mai.

(3) Ƙara ingancin ruwa

(4) Kwanciyar aiki

Gabaɗaya magana, ma'auni na fasaha na tsarin gurguzu ana ƙididdige shi gwargwadon ingancin mai, kuma ma'aunin mai daban-daban a cikin tsarin lalata ya bambanta. Idan kuna da sha'awar tace mai, da fatan za a tuntuɓe mu da tambayoyinku ko ra'ayoyinku. Za mu shirya ƙwararrun injiniyoyinmu don keɓance layin mai da ya dace wanda aka sanye da kayan aikin tace mai daidai a gare ku.